Who Should Make Your Patterns?

Working With Pattern and Sample Makers

January 19, 2012Quantifying Small Run Production

June 14, 2012Do you think you can handle making your own sewing patterns? How about directing someone else to do so? Do you even know the first thing about how to sew or assemble the type of product you want to make?

I’m all for the DIY movement and bootstrapping a startup business, but unless you have prior experience in technical sewing and patternmaking, it’s often in your best interest to hire a professional to make your patterns.

Patternmaking is one of THE MOST CRITICAL elements of developing a successful, manufacturable product.

However, I’ve run across countless designers who want to scrimp and save on this important step, and in many cases they end up sabotaging themselves and their product’s viability in the process.

Trying to save a few hundred dollars on patternmaking could actually cost you hundreds or thousands more in sewing and manufacturing. A good professional pattern should be developed with your price point and method of manufacturing in mind, and the result should be relatively quick and easy to sew.

Unfortunately, the sewer often gets the blame when the finished product doesn’t turn out like the designer envisioned, when in actuality the issues need to be addressed with the patternmaker (or a sloppy cutter – but that’s an entirely different topic!). A good sewer may figure out work-arounds to achieve a decent end result, but keep in mind that these problems may be magnified by average production sewers down the road who produce inconsistent results.

Pattern and construction issues will most likely end up costing more in the long run, so you’re better off dealing with these problems during development. It could save you countless headaches and hassles in production.

Throughout the course of my career, I have worked with a wide range of patterns with varying results, most often based on the competency of the patternmaker. I’ve dealt with the incredible frustration of being given patterns with seams that don’t match up, or pieces that are difficult and time consuming to sew, or even just aren’t possible to construct with the pieces I’ve been given and the machinery I have available.

More often than not, I’m missing specific instructions for how a designer and/or patternmaker intended for seams to be finished, where labels and topstitching should be placed, or what sort of interfacing should be used. Since many of the designers I work with aren’t used to thinking through all of these details, I can provide guidance to some extent, but it is still ultimately the designer’s choice and responsibility – whether they figure it out themselves or pay for a professional to help them establish their specs.

I’m extremely wary of taking on a project when the ability of the pattern maker is questionable, as this often results in more headaches and wasted time than the project is worth, unless the designer is open to paying for a pattern audit and prepared for the possibility that a pattern may have to be remade to meet professional standards. Like many other professionals, I don’t want my name associated with making sub-par products due to things beyond my control such as flawed patterns and amateur design decisions. If you’re too cheap to invest in quality patterns and consultations with industry professionals, then you should reevaluate whether or not you’re serious about being in this business.

Before you rush out and hire the first person who says they can make a pattern for you, read our guide to working with pattern and sample makers first. Then consider your ultimate goals in creating a new product and whether or not the patternmaker you’re considering is indeed an experienced professional. Patternmakers are technical engineers who are trained in building systems for manufacturing; don’t be fooled into thinking that just any designer or seamstress is capable of making your patterns.

Key questions to ask when looking for someone to make your patterns:

- What are their qualifications?

- Does the pattern maker have experience with your particular fabrics/materials, product type, or niche?

- Does the patternmaker understand sizing and fit?

- Does the patternmaker understand factory construction methods?

- Can they refer you to sample sewers and/or production factories?

- Where are they located? How will you communicate? (Local is ideal, but remote Skype meetings can also be a valid option.)

- How do they charge? How much are you willing and able to spend?

- What is their process for sample making and revisions? (Typically it’s best to have a rough sample, often muslin, made up first to check fit and style lines before making a finished quality sample. Often at least 1 round of revisions is necessary before a production pattern and sample can be finalized.)

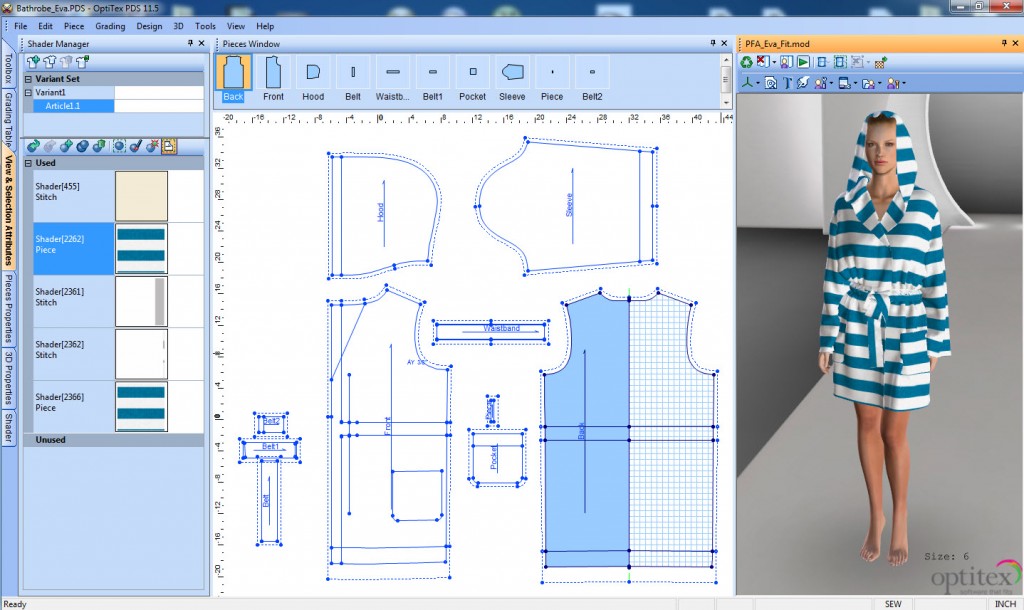

- Do they hand draft patterns or use a computer? (Either method is acceptable, but keep in mind you may need to source an additional contractor to digitize and grade as well as print markers.)

The more prepared you are as a designer, the more likely it is that a professional patternmaker will take you seriously. Do your homework, and you’ll be much happier with the results.